How to Install Blinds and Shades

Installing blinds or shades in your home may seem like a daunting task. Blinds.com is here to make it easy with our Installation Guide!

Keep in mind that the steps in this guide provide a general overview of installing blinds. Depending on your specific product, your installation instructions may vary. Always refer to your specific product for precise installation instructions.

Consult a Professional

Not a DIY person? No need to worry - Blinds.com has professionals waiting to help you with measuring and installation. Click here or call us at 800-689-4496 to find a local professional.

What You Will Need

- Steel Measuring Tape

- Step Ladder (if necessary)

- Screwdriver or drill

- Level tool

Helpful Hints Before You Begin:

- For the most accurate measurements, only use a steel tape measure.

- Your window measurements should have accounted for either an inside mount or an outside mount. An inside mount is installed inside the window recess and provides a clean, finished look. An outside mount rests above the window and covers the entire frame.

- Double check all packaging and make sure you received the correct number of screws, mounts, and hardware with your order before you begin installing.

How to Install Inside Mount Blinds or Shades

The installation process for inside mount blinds may vary slightly depending on your product. These general steps provide an overview for installing inside mount blinds, but always refer to the manufacturer instructions for details specific to your product.

- Position the first bracket in the upper corner of the window frame so that it's level with the wall's surface. Always check your specific product instructions for the exact placement of the brackets. If your blinds came with a decorative valance, you will need to set the brackets further back into the window opening to allow room for the valance.

- Mark the screw locations with a pencil.

- Repeat steps 1 and 2 with the second bracket in the opposite corner of the window frame. If you're mounting into drywall with no studs behind, you will need to use drywall anchors.

- Use a steel tape measure or a level tool to ensure the two bracket locations are even.

- Use a drill bit - smaller than your screws - to drill pilot holes through your bracket marks.

- Screw the brackets in place.

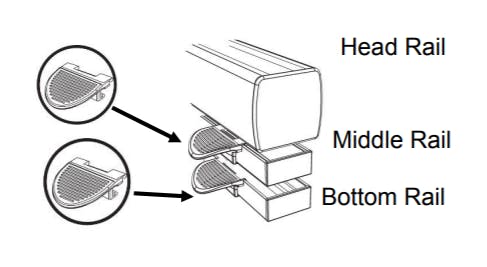

- Install your blinds by sliding the headrail into the brackets, and close the brackets to secure the headrail in place, or snap the headrail into the brackets for other styles.

- Test your blinds by lowering, raising, and rotating them to ensure all parts are functional.

How to Install Outside Mount Blinds or Shades

The installation process for outside mount blinds may vary slightly depending on your product. These general steps provide an overview for installing outside mount blinds, but always refer to the manufacturer instructions for details specific to your product.

- Position the first bracket in the upper corner of the window frame so that it's flush with the wall's surface. Always check your specific product instructions for the exact placement of the brackets.

- Mark the screw locations with a pencil.

- Repeat steps 1 and 2 with the second bracket in the opposite corner of the window frame. If you're mounting into drywall with no studs behind, you will need to use drywall anchors.

- Use a steel tape measure or a level tool to ensure the two bracket locations are even.

- Use a drill bit - smaller than your screws - to drill pilot holes through your bracket marks.

- Screw the brackets in place.

- Install your blinds by sliding the headrail into the brackets, and close the brackets to secure the headrail in place, or snap the headrail into the brackets for other styles.

- Test your blinds by lowering, raising, and rotating them to ensure all parts are functional.

Blinds.com SureFit™ Guarantee

Blinds.com offers an exclusive SureFit™ Guarantee. We make sure you have complete peace of mind when measuring for any product we offer.

If you made a mistake measuring your blind, we’ll remake it at no cost to you. You don’t even pay for the return shipping of your old blind! You only pay if there’s a difference in price between your old and new blind, or if the new blind requires a shipping fee (generally, this applies when it’s over 94" wide).

Important Disclaimer:

- Limit 1 remake per item; 4 item remakes per household per lifetime (unless the error is ours, in which case, we’ll make it right!).

- Same-product exchanges only, within 30 calendar days of receipt of package.

- Changes are restricted to size and mount only.

- Refunds are not offered under this guarantee.

Not covered under this guarantee:

- Commercial orders: any order containing 25 or more of the same product, of tax exempt status, or containing any Blinds.com Commercial brand product.

- Any product ordered outside our recommended sizes or specifications, which can be found on the product page.